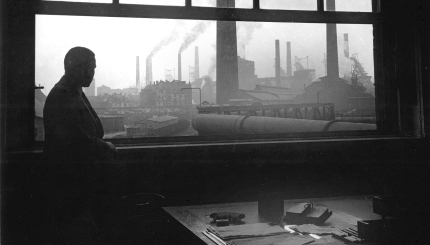

In-house trading and shipping organization established, internationalization of he group

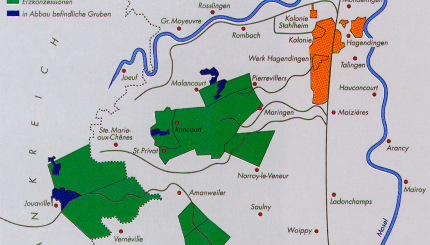

The in-house trading and shipping network is initially geared to the locations of the ore mines acquired and their shipping routes:

To allow iron ore to be transported at low cost via the River Rhine to meet the rising requirements of the Hamborn and Meiderich blast furnace plants, the first step in 1903-1905 is to build the Schwelgern port to supplement the existing Alsum works port. After the Schwelgern port goes into operation, in 1906 Thyssen founds Transportkontor Vulkan GmbH, [Duisburg-]Bruckhausen, with a branch in Rotterdam, in particular to ship ore arriving in Rotterdam up the Rhine.

1910 sees the establishment of N. V. Handels- en Transport Maatschappij Vulcaan, Rotterdam, an ocean shipping company aimed at making the Thyssen group independent of the international freight market.

From 1912 a number of company-owned branch establishments are set up in the Mediterranean area. Freighters can bunker coal there en route to the Russian or Indian ore mines, and can also deliver bunker coal or freight for third parties. This provides the vessels with freight from Rotterdam or Newcastle for at least part of their journey, helping reduce operating costs. In-house branches are established in Algiers, Port Said, Suez, Oran, Naples, Bona, Bizerte, Tangier and Genoa. In 1913 Thyssen turns its attention to Latin America, founding Deutsch-Überseeische Handelsgesellschaft (German Overseas Trading Company) in [Duisburg-]Hamborn with a branch in Buenos Aires. Thyssen's own ships transport ironware to Argentina and return to Europe carrying grain.

/thyssenkrupp_logo_claim_d.svg)